Rust, Rust, and More Rust

When you are grafting in a new steel structure, you want as much surface area as you can to weld to. My friend who's letting me use his slab is also a metal fabricator and jumped in to help knock out the big problems with this trailer. This is his method for cutting and welding in a new frame rail. We went with this much taller frame rail, as the height of it overall was the same as the original frame plus the 2" drag section at the bottom. I also left it long, as I plan on placing the condenser for a split unit on the back.

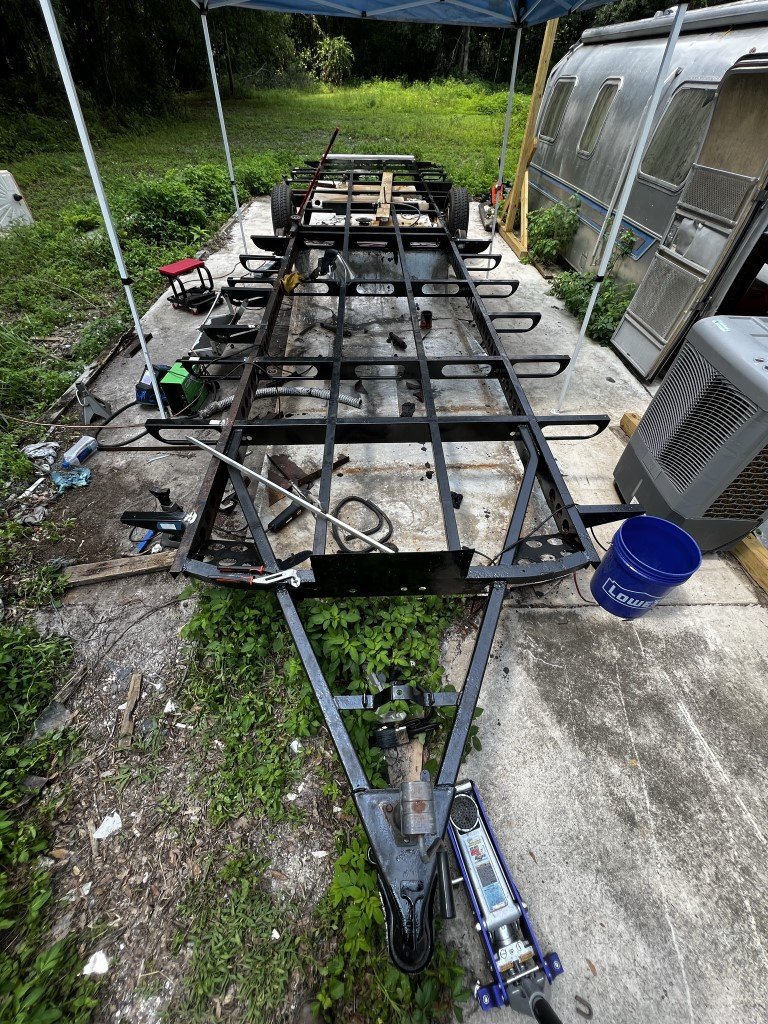

What started out as a "fix the rear rot and only replace outriggers that have turned to dust" turned into "replace the entire rear 6' section of the frame, ALL BUT THREE outriggers, and weld every joint that wasn't welded by the factory."

I began wire-wheeling the entire frame and preparation for POR-15, and began to notice some areas I had overlooked. A couple of spots on the frame on the door side were rusted through and the frame was kinked just behind the door. I hit the bulk of the frame with POR-15.

Now it's time to tackle the other frame rail in the rear. Those of you with a keen eye will notice I upgraded trucks. The sections of frame that were cut out and replaced were where the outriggers for the steps were - the kinked area from the earlier photos.

DING! Frame is done!

I go to Miami next!